| 全國(guó)24小時(shí)咨詢熱線 86-027-89353268 13419620038 |

歡迎訪問(wèn)武漢恒達(dá)昌機(jī)械設(shè)備有限公司官方網(wǎng)站!

Pharma lifter, for bin

用途

該機(jī)主要應(yīng)用于制藥工業(yè)固體物料的輸送、加料。可與混合機(jī)、壓片機(jī)、膠囊填充機(jī)等設(shè)備配套使用。同時(shí)在制藥、化工、食品等行業(yè)中廣泛使用。

APPLICATION

The machine is mainly used for conveying and charging solid materials in the pharmaceutical industry. It can work with the mixer, tablet press, capsule filler, etc. It is also widely used in such industries as medicine, chemical industry, food, etc

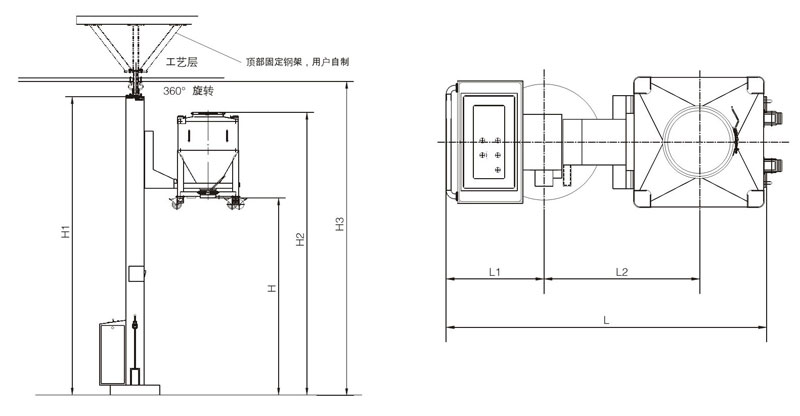

原理

該機(jī)主要由底盤、立柱、提升系統(tǒng)等部件組成。工作時(shí),先將裝有物料的料斗推入料斗提升機(jī)的叉架上,然后啟動(dòng)提升按鈕,料斗做提升運(yùn)動(dòng),料斗到位后轉(zhuǎn)動(dòng)底盤與加料的設(shè)備密閉對(duì)接,開啟出料蝶閥,使物料密閉轉(zhuǎn)移到下一個(gè)工序。

PRINCIPLE

The machine is mainly composed of chassis, column, lifting system, etc. When it works, push the hopper loaded with materials into the lifting crotch of the hopper lifter. Press the lifting button and the hopper will make lifting movement. After the hopper reaches the designated position, rotate the chassis to realize closed connection with the charging equipment. Start the discharging butterfly valve to transfer the materials to the next procedure

特點(diǎn)

◆機(jī)體外殼用奧氏不銹鋼制造,無(wú)死角、無(wú)凹凸、光潔易清洗。

◆料斗采用優(yōu)質(zhì)奧化體不銹鋼SUS304或SUS316L精制加工,內(nèi)壁表面精糙度(R≤0.2μm),特制出料蝶閥,無(wú)死角、無(wú)殘留、易清洗。

◆與下工序設(shè)備可用特制的軟管連接,或按需要配置自動(dòng)放料閥。

◆可提升不同規(guī)格的料斗。

FEATURES

The body shell is made of austenitic stainless steel, no dead angle, no bump, smooth and easy to clean

The hopper is made of high-quality austenitic stainless steel SUS304 or SUS316L. The surface roughness of the inner wall (RsO.2 u m), special butterfly valve, no dead angle, no residue, easy to clean

The special process hose can be connected with the lower process equipment, or the automatic discharge valve can be configured as needed

The hopper can be upgraded in different specifications

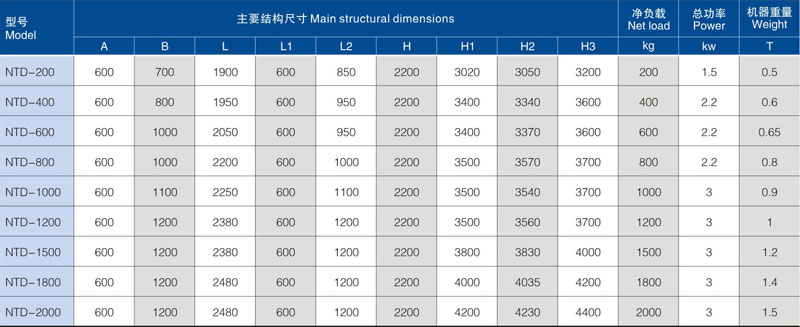

主要技術(shù)參數(shù) MAIN TECHNICAL PARAMETERS

本公司可按用戶特殊要求定制生產(chǎn),如有變動(dòng),恕不預(yù)先通知!

Our company can customize the products according to special requirements of users. you will not be notified of any changes in advance