| 全國24小時咨詢熱線 86-027-89353268 13419620038 |

LHSZ高位濕法混合制粒機

High platform wet granulator

原理

粉狀物料通過配料系統(tǒng)加到混合容器中,先經底部攪拌槳旋轉推動做流化態(tài)運動,并得到充分混合,然后經壓力噴槍注入粘合劑,使干粉變成濕潤軟材,同時在攪拌槳和側壁高速切刀的雙作用下制成均勻濕顆粒。

PRINCIPLE

The powder materials are fed into the mixing vessel through the dispensing system. Through rotation and push by the mixing get sufficient mixing. Then the adhesive is injected through theo paddle at the bottom, they first move under a fluidizing status pressure spray gun to turn the dry powders into wet and soft materials. Meanwhile, they are made into even wet granules under the double actions of the mixing paddle and the high-speed cutter on the side wall.

特點

◆整機采用優(yōu)質不銹鋼制造

◆設有特制攪拌桶,錐柱復合型結構,內壁轉角光滑過渡,鏡面拋光,不沾料,易清洗

◆物料在密閉攪拌桶中,一步即可完成混合制粒工序

◆采用門LC控制,攪拌制粒電機變頻調速,全部操作分手動和自動

◆裝有聯(lián)鎖保護裝置,操作更安全

◆配有打印機,可自動打印所有工藝參數,原始記錄與實際相符

◆可配濕法整粒機和搖擺顆粒機,與沸騰干燥機連線,組成全封閉的制粒生產線

FEATURES

The whole machine is made of high quality stainless steel

Special mixing barrel, tapered column composite structure, smooth transition of inner wall corner, mirror polishing, no material, easy to clean

The material is in a closed mixing tank, and the mixing granulation process can be completed in one step

Using PLC control, mixing granulating motor frequency control all operations are manual and automati

Equipped with interlocking protection device for safer operation

With printer, all process parameters can be printed automatically, and the original record matches the actual oIt can be equipped with wet granulator and rocking granulator, and connected with boiling dryer to form a fully enclosed granulation production line

用途

該機是制藥工業(yè)固體制劑生產中普遍使用的工藝設備之一。它具有混合、制粒等多種功能 ,廣泛應用于制藥、食品、化工等行業(yè)。

APPLICATION

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing granulating, etc. It is widely used in such industries as medicine, food chemical industry, etc.

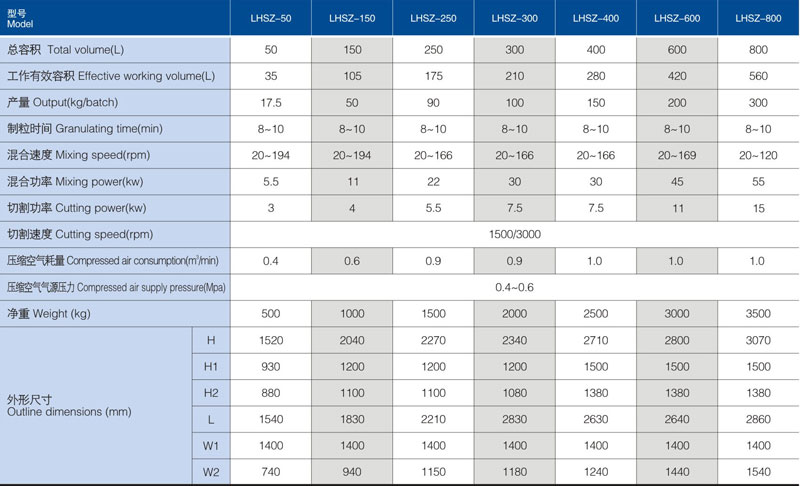

主要技術參數 MAIN TECHNICAL PARAMETERS

公司可按用戶特殊要求定制生產,如有變動,恕不預先通知!

Our company can customize the products according to special requirements of users. you will not be notified of any changes in advance